Reducing energy loss in the boiler room

With the current global emphasis on reducing Co2 emissions there is an ever increasing focus on minimising energy loss in the built environment.

The Boiler Room is generally regarded as the heat centre of the building. It is worthwhile making every effort to retain as much heat in the boiler house pipe-work as possible ready for distribution into the building.

A warm or hot boiler house is loosing heat to the environment. Expensive fossil fuel has been burnt to create this heat.

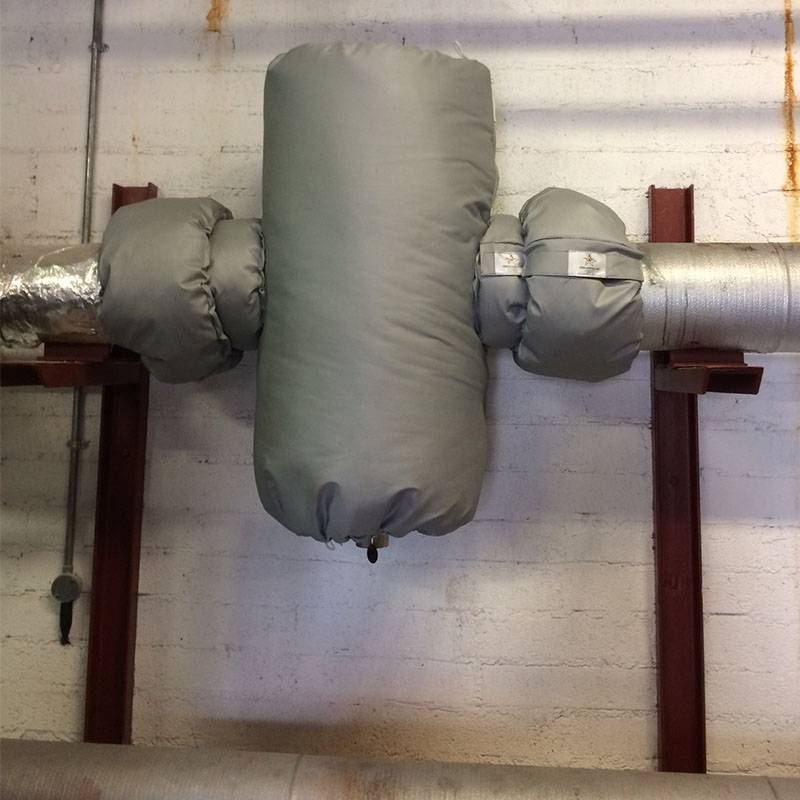

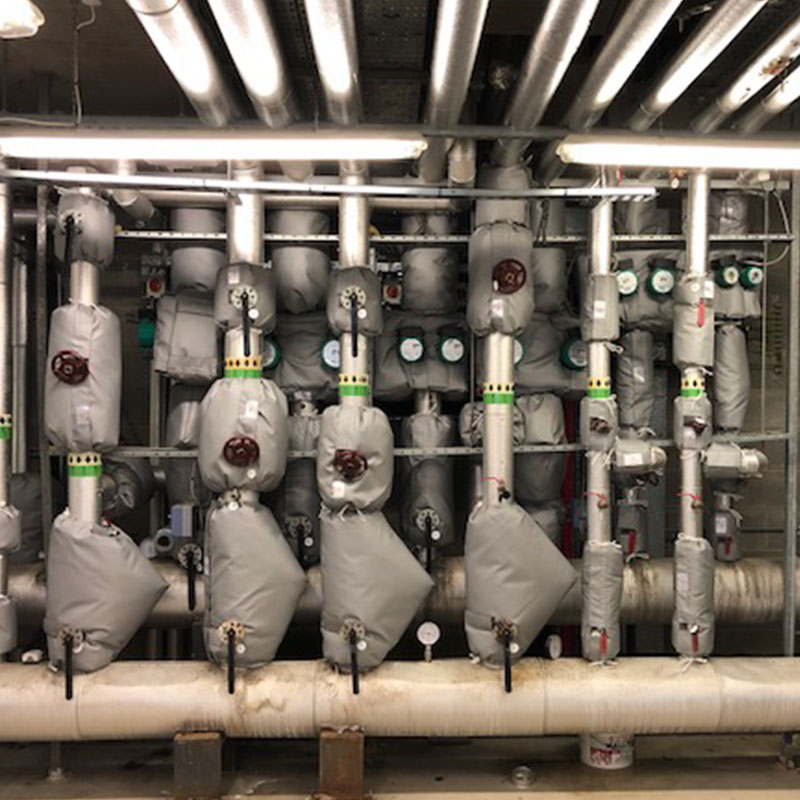

GEM’s insulation jackets provide exceptional heat saving for those difficult to cover aspects of boiler room pipe-work.

GEM has been supplying thermal insulation jackets to Irish companies and organisations for more than 10 years.

How our insulation jackets are made:

All covers are sewn and conform to the configuration of the items been insulated.

The insulation jackets include openings for all protrusions e.g. pipes, glands, control valves, screws, levers, motorised valves, extensions and spurs etc.

They are designed so that no force bending or folding the cover is necessary for installation.

The insulation infill is fabricated in one piece wherever possible to prevent insulation settlement.

Purpose made quilting pins are used to secure insulation on very large jackets.

Insulating infill with more than one piece has staggered joints to prevent hot spots and heat loss.

Our Complete Bespoke Service

Initial pipe-work survey

All large exposed pipe-work is measured

A complete bespoke specification is drawn up

A purpose designed Energy Calculator is used to assess annual savings

A costing is given with built in Return on Investment

Covers are manufactured and delivered on site

Fitting is completed by GEM

GEM handover to site

Boiler house temperatures are logged before and after fitting

GEM Heat loss calculations

All heat loss calculations are based on one valve losing the equivalent amount of heat as one metre of the same un-insulated pipe.

%

Our insulation jackets reduce heat loss by 91%

What are the benefits of insulating pipework?

Significant reduction of heat loss from boilers to surrounding air

Reduces energy costs (average size boiler house circa €3,000 PA)

Heat protection for boiler room electronic equipment

Personal Protection from Heat Fatigue and Possible Burns

Improved delivery of Hot Water

Good mechanical wear resistance

Non-asbestos

Resistant to most chemical attacks

Non combustible

Easily cleaned

Quick fitting and easy release

Where can insulation jackets be applied?

- Flanges

- Gate Valves

- Screw Valves

- Strainers

- Control Valves

- 3-port Valves

- Calorifier Manifolds

- Plate Heat Exchangers

- Header Ends

- Air & Dirt Separators

News:

Shannon Leisure Centre Cover Up

Gem insulation jackets engaged with Shannon Leisure Centre to survey their exposed pipework which was losing heat to the environment. Part of the work involved a complex header configuration with pipework gaps A bespoke jacket was manufactured to fit snugly in place....

Gem Insulation Jackets for Thermal Skids

Jackets can be installed to large process skid packages to incorporate protection on valves, piping and vessels. Gem Insulation Jackets are used extensively by skid packaging companies for thermal insulation and winterisation covers across a range of equipment using a...

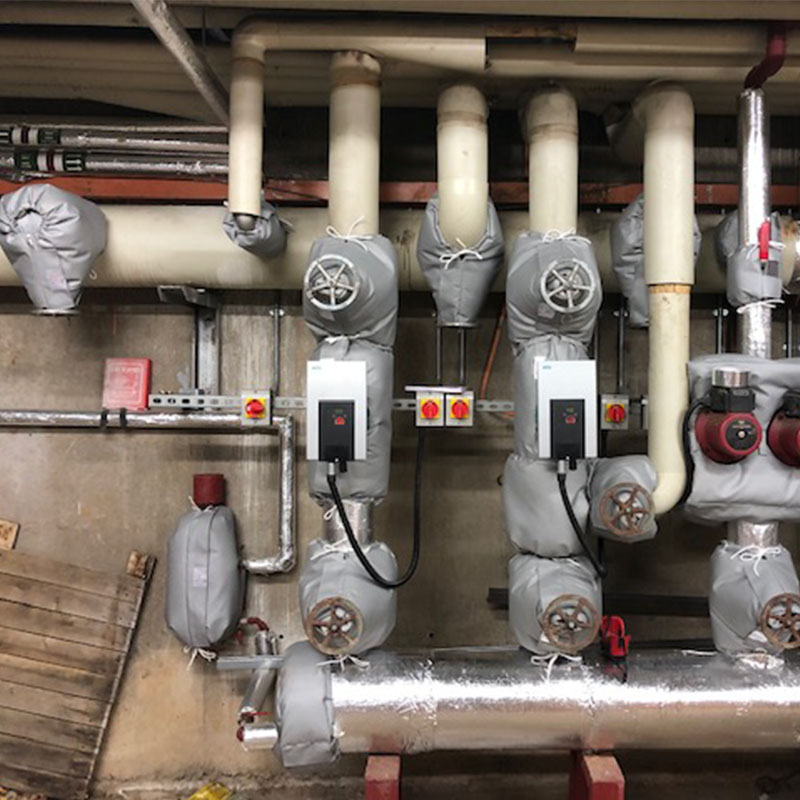

Gem Insulation Jackets for Pumps

Gem insulation jackets fits snugly around the pump body and flange leaving the pump air intake free and leaving the associated VSDs free to ensure the pump does not overheat. Gem Insulation Jackets can be specified for single and double pump sets. Gem single pump...

Our Clients:

or send us a message…